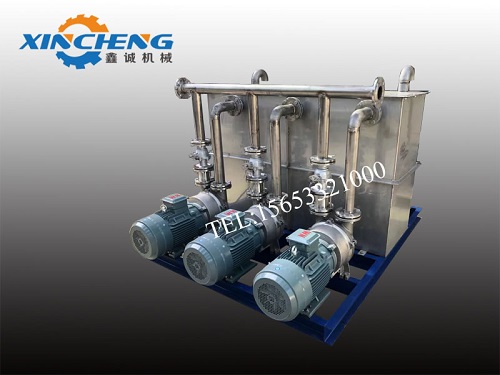

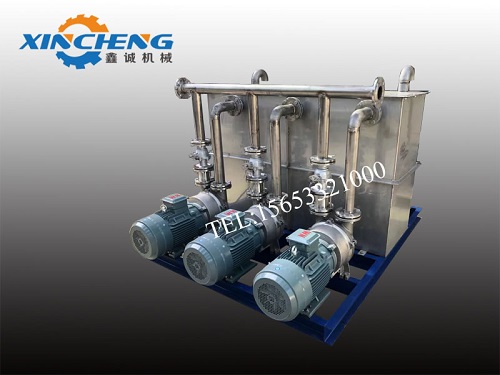

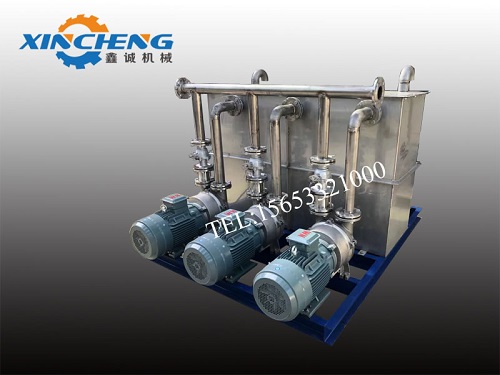

Closed cycle vacuum unit

Date of issue:2021/9/23 9:20:39 Number of Views:

1.The normal operation of the water ring pump requires a large amount of working fluid. The working fluid consumption of pumps of different sizes varies from 0.12 m3/h to 50 M3/h per hour, that adds up to a huge amount of water consumption every day, every month, every year. The application of water ring pump closed circulation unit can avoid the waste of a large amount of working fluid. 2, in chemical enterprises, contains toxic and harmful liquid, or the removal of flammable and explosive gas, the circulation of liquid is not allowed to communicate with the outside world, thus avoiding pollution in the workplace, closed cycle unit, the application of stainless steel + mechanical seal can solve this kind of problem. 3. Under the condition that the quality of the water source can not be guaranteed, the water scale is serious within a very short period of operation, which affects the normal operation of the pump. A softening tank can be added in front of the pump to form a similar closed-loop unit, and the level of the liquid can be monitored to continuously replenish the soft water, can ensure the good operation of the system. 4. In order to make the operation of the system stable and reliable, the pump unit can be set up in one-on-one or more-on-many type, several pumps can be opened at the same time when the pump is started, and the system can meet the technological requirements in the shortest time, and then the unit instrument can return the signal after monitoring, electric Control or remote hole close spare pump, only one or several pumps to maintain the system vacuum, reduce the power of the whole system, shorten the process time, improve the automation. 5, large water ring complete sets of units can be used for gas drainage, pressure swing adsorption, transportation and filtering industries. Our company designed a complete set of mobile gas pumping station, and equipped with a sound monitoring and control system, all supporting 2BE products are certified by the coal safety, to ensure the unit's reliable operation. 6. On the occasion of removing airtight container, such as drying system, the vacuum in the system is much higher than that of water-ring pump, which can be connected in series with roots pump to form roots-water-ring unit to increase air volume and limit vacuum to meet the requirement. Three roots unit limit vacuum can be about 0.5 PA. 7, the application of high-pressure water ring compressor must add a post-separator, which belongs to the category of pressure vessels, plays the role of gas-water separation, stable pressure transmission, and can provide circulating liquid, this kind of compressor can compress the gas produced in chlor-alkali industry, such as hydrogen and Acetylene. It is usually equipped with heat exchanger, centrifugal pump and other accessories, the utility model is convenient for users to install and Debug, and saves the tedious work of users to install pipelines.

1.The normal operation of the water ring pump requires a large amount of working fluid. The working fluid consumption of pumps of different sizes varies from 0.12 m3/h to 50 M3/h per hour, that adds up to a huge amount of water consumption every day, every month, every year. The application of water ring pump closed circulation unit can avoid the waste of a large amount of working fluid. 2, in chemical enterprises, contains toxic and harmful liquid, or the removal of flammable and explosive gas, the circulation of liquid is not allowed to communicate with the outside world, thus avoiding pollution in the workplace, closed cycle unit, the application of stainless steel + mechanical seal can solve this kind of problem. 3. Under the condition that the quality of the water source can not be guaranteed, the water scale is serious within a very short period of operation, which affects the normal operation of the pump. A softening tank can be added in front of the pump to form a similar closed-loop unit, and the level of the liquid can be monitored to continuously replenish the soft water, can ensure the good operation of the system. 4. In order to make the operation of the system stable and reliable, the pump unit can be set up in one-on-one or more-on-many type, several pumps can be opened at the same time when the pump is started, and the system can meet the technological requirements in the shortest time, and then the unit instrument can return the signal after monitoring, electric Control or remote hole close spare pump, only one or several pumps to maintain the system vacuum, reduce the power of the whole system, shorten the process time, improve the automation. 5, large water ring complete sets of units can be used for gas drainage, pressure swing adsorption, transportation and filtering industries. Our company designed a complete set of mobile gas pumping station, and equipped with a sound monitoring and control system, all supporting 2BE products are certified by the coal safety, to ensure the unit's reliable operation. 6. On the occasion of removing airtight container, such as drying system, the vacuum in the system is much higher than that of water-ring pump, which can be connected in series with roots pump to form roots-water-ring unit to increase air volume and limit vacuum to meet the requirement. Three roots unit limit vacuum can be about 0.5 PA. 7, the application of high-pressure water ring compressor must add a post-separator, which belongs to the category of pressure vessels, plays the role of gas-water separation, stable pressure transmission, and can provide circulating liquid, this kind of compressor can compress the gas produced in chlor-alkali industry, such as hydrogen and Acetylene. It is usually equipped with heat exchanger, centrifugal pump and other accessories, the utility model is convenient for users to install and Debug, and saves the tedious work of users to install pipelines.

- Previous:Closed cycle vacuum unit

- Next:没有了!